Total: £8.95

Introduction

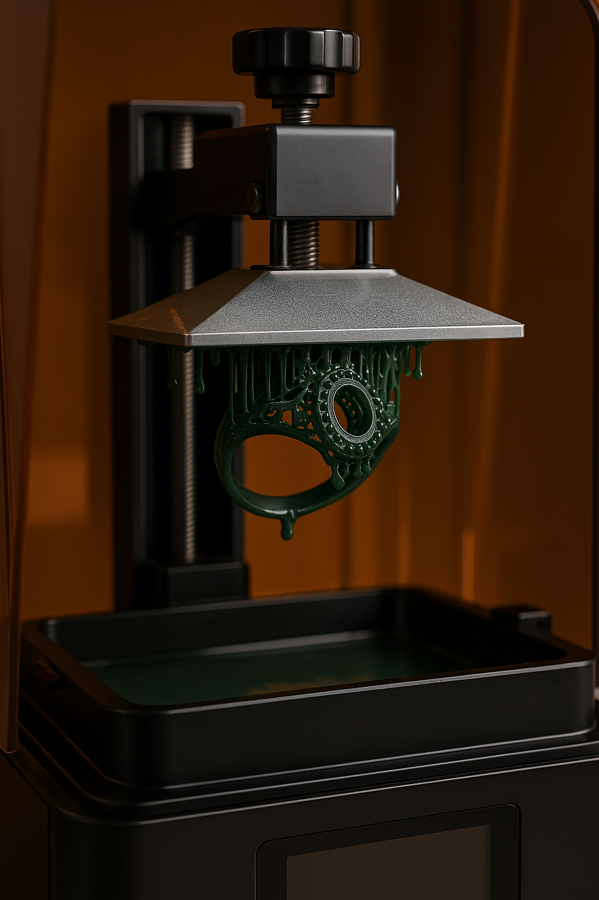

One of the critical parameters influencing the overal quality and mechanical properties of 3d printed products is the accuracy of the filament diameter used during the printing process. Even slight variations in diameter can lead to significant defects, affecting both aesthetics and functionality. This article explores the significance of filament diameter accuracy in ensuring superior surface quality and structural strength in 3D-printed models, along with best practices for maintaining precision.

1. Understanding Filament Diameter Accuracy in 3D Printing

1.1 Definition of Filament Diameter Accuracy

3D printing filament diameter accuracy refers to the consistency of filament diameter across its length. It ensures uniform material flow during extrusion, reducing variability in printed models. This parameter is crucial for maintaining print quality, especially in precision engineering applications.

1.2 Measurement and Tolerances

Filament manufacturers specify diameter tolerances, typically ±0.02 mm to ±0.05mm for high-quality filaments. Inconsistencies beyond this threshold can result in unreliable extrusion, affecting print accuracy and durability. Measuring tools like digital callipers and laser micrometres help in assessing these tolerances, ensuring that only materials within the accepted range are used.

1.3 The Role of Nozzle Diameter

The nozzle diameter significantly influences how filament variations impact print quality. A larger nozzle may be more forgiving, while smaller nozzles used for high-detail prints require highly consistent filament diameters to prevent blockages and inconsistent extrusion.

2. Impact of Diameter Accuracy on Surface Quality

2.1 Layer Consistency and Print Artifacts

Inconsistent filament diameter leads to fluctuations in extrusion, causing under-extrusion (gaps and weak layers) or over-extrusion (bulging and surface roughness). These artifacts impact the aesthetic and functional quality of prints, often requiring additional post-processing to correct surface defects.

2.2 Surface Smoothness and Precision

Precise diameter control ensures even layer deposition, leading to smoother surfaces with minimal post-processing requirements. This is particularly crucial for models requiring fine details and high-resolution printing, such as detailed prototypes, dental models, and figurines.

2.3 Reduction of Stringing and Oozing

Filament diameter inconsistencies affect extrusion rates, contributing to excessive oozing and stringing, which degrade the overall finish of the model. This is especially problematic in materials like TPU and PETG, where precise extrusion control is necessary to minimize artifacts.

2.4 Effects on Support Structures

When filament diameter accuracy fluctuates, support structures can become weak or overly rigid, making them difficult to remove cleanly. This can damage delicate models, necessitating careful tuning of filament consistency to maintain the balance between strength and removability.

3. Influence of Filament Diameter Accuracy on Strength and Mechanical Properties

3.1 Interlayer Bonding and Structural Integrity

Variations in filament diameter impact material flow and layer adhesion. Poor bonding weakens structural integrity, making prints susceptible to delamination and failure under load. Proper interlayer adhesion is crucial for applications requiring durable and functional components, such as automotive parts and medical devices.

3.2 Uniformity in Stress Distribution

Consistent extrusion leads to even stress distribution within the printed model, enhancing its mechanical performance. In contrast, fluctuations in material feed create weak points prone to cracking under mechanical stress. This is particularly relevant for engineering applications where tensile and compressive forces must be evenly distributed.

3.3 Impact on Load-Bearing Capacity

For load-bearing components, precision in filament diameter ensures accurate infill density and wall thickness, directly affecting strength and durability. High-performance filaments such as carbon-fibre-reinforced PLA and nylon rely heavily on accurate filament diameter to maintain mechanical integrity.

3.4 Effect on Functional Prints and Moving Parts

Functional prints, such as gears, bearings, and articulated parts, require precise material flow for tight tolerances. Filament diameter inaccuracies can lead to poor fitment, excessive friction, or mechanical failure in moving parts.

4. Factors Influencing Diameter Accuracy and How to Control Them

4.1 Filament Manufacturing Quality

High-quality filaments undergo rigorous testing for consistent diameter control. Choosing reputable suppliers reduces the risk of variations. Some premium filaments come with a certificate of diameter consistency, ensuring reliability.

4.2 Printer Calibration and Extruder Setup

Regular calibration of the extruder, including checking stepper motor settings and nozzle size, ensures accurate material flow and compensates for minor filament inconsistencies. Factors such as extrusion multiplier (flow rate) adjustments in slicer settings help compensate for slight variations.

4.3 Storage and Handling

Filaments can absorb moisture, causing swelling and inconsistency in diameter. Proper storage in airtight containers with desiccants preserves filament quality. Moisture-sensitive materials like nylon and PVA require additional drying before use to prevent extrusion problems.

4.4 Effect of Temperature on Filament Behaviour

Extreme temperatures during filament storage or printing can affect diameter consistency. Thermal expansion can cause extrusion variations, making temperature control an important factor in maintaining dimensional stability.

5. Practical Considerations for High-Quality Prints

5.1 Selecting the Right Filament for Strength and Surface Quality

Choosing the right material, such as PLA for smooth surfaces or ABS for toughness, in combination with precise diameter control, optimizes print performance. For high-strength applications, materials like polycarbonate and carbon-fibre-reinforced filaments require tight tolerance control.

5.2 Using Advanced Extrusion Compensation Techniques

Modern slicers incorporate compensation settings to adjust for filament inconsistencies, improving print accuracy and reliability. Flow rate adjustments, retraction tuning, and extrusion width fine-tuning help counteract minor diameter fluctuations.

5.3 Post-Processing Techniques for Enhanced Surface Finish

Even with precise diameter control, techniques like sanding, vapor smoothing, or resin coating can further refine surface quality. Chemical smoothing, such as acetone vapor treatment for ABS, can enhance surface finish by dissolving minor inconsistencies.

5.4 Testing and Quality Control Measures

Using test prints such as calibration cubes and extrusion flow tests can help detect filament inconsistencies before starting a critical print. Implementing quality control measures ensures that filament diameter variations do not compromise print integrity.

Conclusion

Filament diameter accuracy in 3D printing is a fundamental factor affecting both surface quality and mechanical strength. Ensuring precise filament control enhances layer consistency, reduces print defects, and optimizes the structural integrity of the final model. By selecting high-quality materials, calibrating printers, implementing extrusion compensation, and monitoring filament storage conditions, manufacturers and hobbyists can achieve superior 3D-printed results with minimal defects. Understanding and controlling filament diameter accuracy will not only improve the aesthetic appeal of prints but also enhance their durability and functionality, making it a crucial consideration in professional and industrial 3D printing applications.