Currently Empty: £0.00

Design & Prototyping Services

- Home

- Design & Prototyping Services

Design & Prototyping Services Using Advanced 3D Printing Technologies

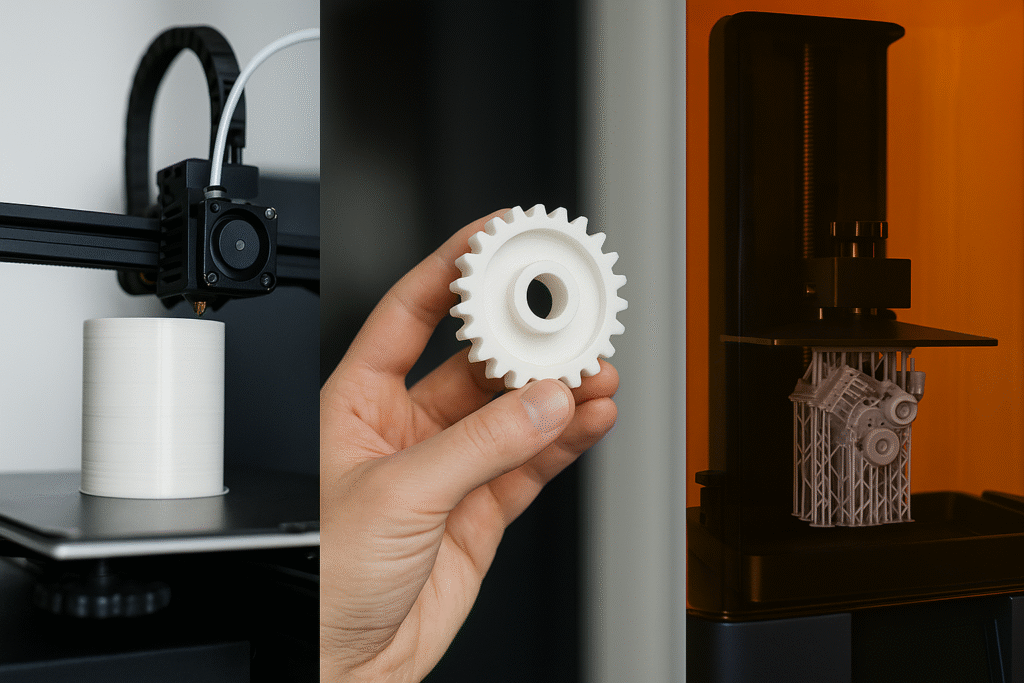

At Fusionise Ltd, we specialize in transforming your innovative ideas into tangible, high-quality prototypes through our precision-driven design and rapid prototyping services, powered by advanced additive manufacturing technologies. Leveraging the capabilities of Fused Deposition Modeling (FDM) and Masked Stereolithography (MSLA) 3D printing, we offer tailored solutions that meet the demands of both functional and aesthetic prototyping across a wide range of industries.

Whether you’re an entrepreneur developing a minimum viable product, an engineer testing mechanical components, an artist bringing creative concepts to life, or a researcher validating experimental designs, our expert team provides end-to-end support—from 3D CAD modeling and material consultation to high-precision printing and post-processing.

Our technology-driven approach ensures fast turnaround times, cost-effective production, and exceptional quality, allowing you to iterate quickly and efficiently. With a strong focus on accuracy, reliability, and design optimization, Fusionise Ltd is your trusted partner in accelerating product development and innovation through the power of modern 3D printing.

Our Capabilities

Product Design & 3D Modelling

At Fusionise Ltd, we offer complete and professional product design and 3D modelling services, helping you turn your ideas into functional and manufacturable digital prototypes ready for 3D printing. Whether you’re starting with a rough sketch, physical sample, or simply a vision, our experienced design team is here to guide you through every stage of the development process—from concept to CAD.

Using advanced CAD software such as SolidWorks, Fusion 360, and Blender, we create high-precision 3D models that are visually accurate and structurally sound and optimized for additive manufacturing. Our designs are tailored specifically to meet the requirements of Fused Deposition Modeling (FDM) and Masked Stereolithography (MSLA) technologies, taking into account critical factors such as:

- Material selection and mechanical properties

- Print orientation and support optimization

- Dimensional accuracy and tolerance control

- Wall thickness, infill, and structural reinforcements

- Ease of assembly and post-processing

We also offer reverse engineering services, where we can replicate existing physical parts by measuring, redesigning, and improving their digital counterparts. For clients with early-stage ideas, we provide concept development and visual prototyping, allowing you to visualize and test your product virtually before committing to print.

Every model is reviewed and validated through printability checks, error corrections, and file optimization (STL/OBJ) to ensure smooth and successful printing with minimal risk of failure.

Whether you’re an inventor, product developer, startup, or industrial designer, our goal is to provide you with a robust, accurate, and ready-to-print 3D model that meets your functional requirements and accelerates your product development cycle.

FDM 3D Printing Services

At Fusionise Ltd, our FDM 3D printing services offer a robust and versatile solution for producing strong, functional, and cost-effective prototypes or end-use parts. Using professional-grade FDM printers, we manufacture components layer-by-layer from high-performance thermoplastic filaments, making this method ideal for both rapid prototyping and low-volume production runs.

FDM technology is known for its excellent mechanical strength, dimensional accuracy, and material versatility, making it the go-to choice for a wide range of engineering and industrial applications.

Key Features of Our FDM Services:

- Strong Layer Bonding: Provides structural integrity suitable for functional use.

- Cost-Efficient: Lower material and machine costs make FDM ideal for early-stage testing and affordable iterations.

- Fast Turnaround: Rapid printing speeds and minimal post-processing reduce lead times.

We print with a broad selection of engineering-grade filaments, allowing you to match material properties to your application:

- PLA (Polylactic Acid) – Easy to print and biodegradable; ideal for visual models and concept validation.

- ABS (Acrylonitrile Butadiene Styrene) – Durable and heat-resistant; suitable for functional prototypes and enclosures.

- PETG (Polyethylene Terephthalate Glycol) – Strong, flexible, and chemically resistant; ideal for mechanical parts and load-bearing applications.

- TPU (Thermoplastic Polyurethane) – Flexible and wear-resistant; perfect for seals, gaskets, and soft-touch components.

- Carbon-Fibre Reinforced Filaments – Enhanced stiffness, strength, and dimensional stability; excellent for lightweight structural components.

Typical Applications:

- Mechanical prototypes and end-use parts

- Tooling, jigs, and fixtures for manufacturing

- Custom enclosures and brackets

- Educational models and demonstration tools

- Spare parts and replacement components

Whether you’re designing a new mechanical system, testing a custom fixture, or producing end-use functional parts, our FDM 3D printing solutions offer a scalable, reliable, and efficient pathway to bring your ideas into reality.

MSLA 3D Printing Services

At Fusionise Ltd, our MSLA 3D printing services deliver ultra-high-resolution, highly detailed, and smooth-surfaced parts ideal for applications requiring exceptional precision and fine surface finishes. MSLA (Masked Stereolithography) is a resin-based additive manufacturing technology that uses an array of UV LEDs shining through an LCD mask to selectively cure photopolymer resin layer by layer.

This process allows for the simultaneous curing of entire layers, making it not only faster than traditional SLA but also capable of achieving micron-level resolution. MSLA is particularly suitable for industries and applications where dimensional accuracy, surface aesthetics, and delicate geometries are critical.

Key Features of Our MSLA Services

- High Resolution: Achieves feature details as small as 35 microns, capturing even the most intricate geometries.

- Exceptional Surface Quality: Produces ultra-smooth surfaces with minimal visible layer lines, reducing the need for post-processing.

- Fast Layer Curing: Entire layers are cured at once, allowing faster print times for dense, complex models.

- Minimal Support Scarring: Ideal for presentation models or client-facing prototypes.

- Material Versatility: Offers a variety of engineering and specialty resins tailored to different mechanical, thermal, and aesthetic needs.

We work with a wide range of advanced photopolymer resins to meet different project requirements:

- Standard Resin – Great for visual models and general-purpose prototyping.

- Tough Engineering Resin – Designed for high impact resistance and durability.

- Flexible Resin – Offers rubber-like properties for gaskets, grips, and wearable components.

- High-Temperature Resin – Suitable for tooling, molding, and heat-resistant applications.

- Castable Resin – Perfect for direct investment casting in jewelry and dental applications.

- Biocompatible Resin – For dental models, surgical guides, and research prototypes in healthcare.

Typical Applications

- Product Design & Industrial Prototypes – Concept models, fit/form testing, and showpieces.

- Jewelry & Miniatures – Master patterns and fine-featured designs for direct casting or display.

- Dental Models & Orthodontics – High-accuracy anatomical models and surgical templates.

- Precision Engineering – Complex geometries, micro-assemblies, and presentation-grade components.

- Consumer Goods – Wearables, accessories, and decorative elements with refined surface finishes.

Whether you’re crafting finely detailed components, functional prototypes requiring surface accuracy, or production-grade castable masters, Fusionise Ltd’s MSLA printing services provide the resolution and performance needed to elevate your design to the next level.

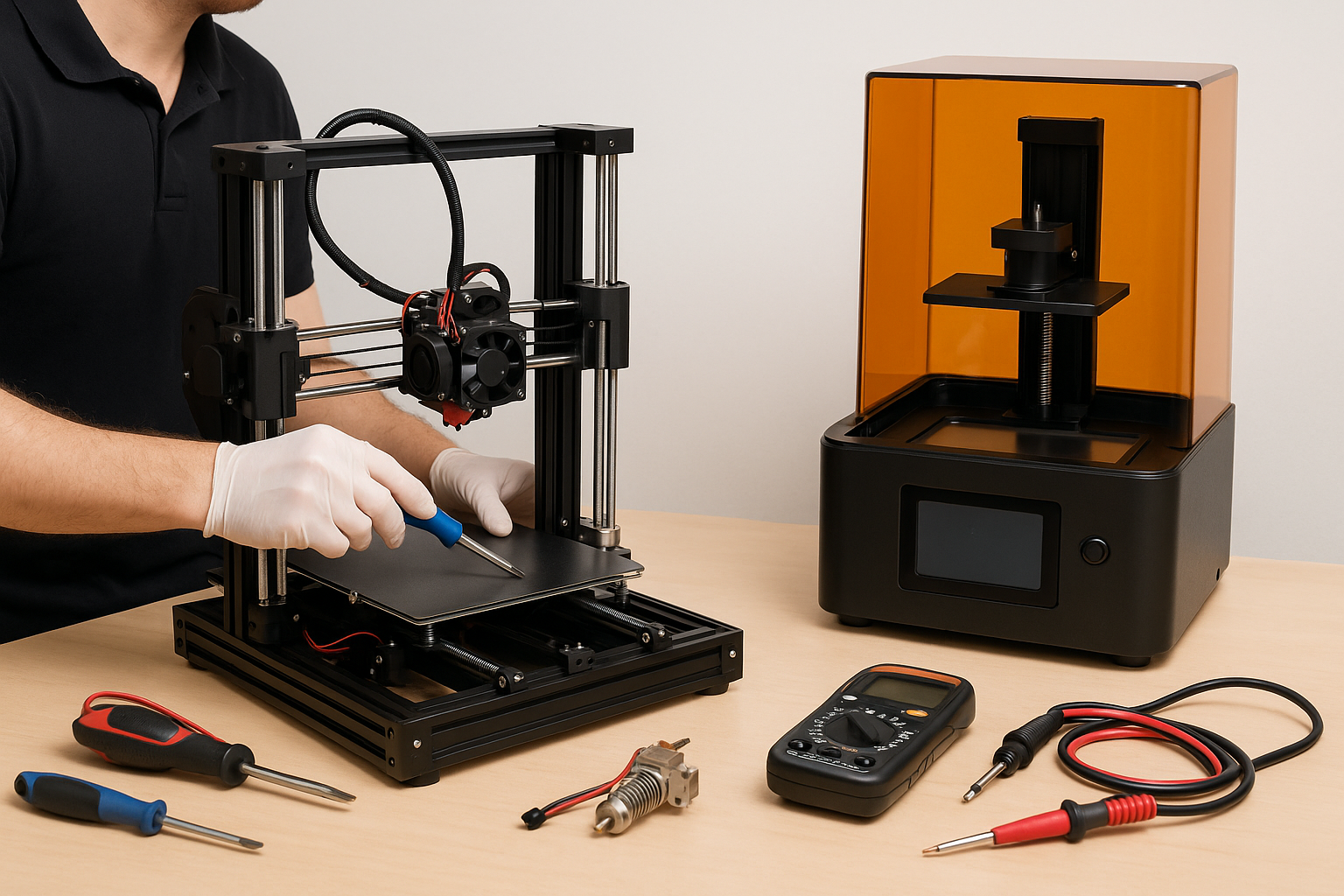

3D Printer Repair & Maintenance Services

At Fusionise Ltd, we offer professional repair and maintenance services for both Fused Deposition Modeling (FDM) and Masked Stereolithography (MSLA) 3D printers. Our goal is to help you keep your machines running at peak performance with minimal downtime—whether you’re a hobbyist, educator, or business user.

What We Offer:

- Full Diagnostics & Troubleshooting: Comprehensive mechanical and electrical assessments to identify and resolve performance issues.

- Hardware Repairs & Part Replacement: Repair or replacement of components such as extruders, motors, hotends, thermistors, UV arrays, LCDs, and more.

- Precision Calibration: Accurate bed leveling, Z-offset tuning, exposure time adjustment, and resin vat alignment for optimal print quality.

- Firmware & Software Updates: Installation and configuration of firmware upgrades and slicing software support.

- Preventative Maintenance Plans: Scheduled servicing to reduce failure risks and extend the lifespan of your 3D printer.

- On-Site or Drop-Off Options: Flexible service delivery based on your location and needs.

We Service All Major Brands:

Bambu Lab, Elegoo, Anycubic, Creality, Prusa, FlashForge, Phrozen, and others.

Whether you’re dealing with print failures, mechanical wear, or electronic faults, our experienced technicians are here to get your printer back in action quickly and reliably.

3D Printing Training & Education Services

Fusionise Ltd offers hands-on training programs designed to empower beginners, students, educators, and professionals with the knowledge and skills needed to succeed in 3D printing. Our flexible training modules cover both FDM and MSLA technologies, combining theory with practical experience.

What We Offer:

- Beginner to Advanced Training: Learn the fundamentals of FDM and resin printing, including hardware setup, slicing software, and printer operation.

- Design for 3D Printing: Understand how to prepare models for additive manufacturing, including file repair, orientation, support structures, and post-processing.

- Troubleshooting & Optimization: Identify and resolve common print issues, improve surface finish, reduce failures, and select the right materials for your needs.

- Curriculum for Schools & Teams: Custom training for educational institutions, engineering teams, and workshops, tailored to your group’s goals and experience level.

- Flexible Delivery: Choose from one-on-one training, group workshops, or remote learning sessions via video conferencing.

Ideal For Educators, students, engineers, hobbyists, designers, and small businesses looking to master 3D printing and accelerate innovation through hands-on learning.

Why Choose Us?

At Fusionise Ltd, we combine advanced technology with expert knowledge to offer an end-to-end solution for all your design and prototyping needs. Whether you’re developing a product from scratch or refining an existing design, here’s why we stand out:

Professional Design Support

Our in-house team of skilled engineers and designers work closely with clients at every stage—from initial concept development to final 3D model preparation. We specialize in Design for Additive Manufacturing (DfAM), ensuring your models are not only innovative but also optimized for performance, durability, and printability.

Industrial-Grade FDM & MSLA 3D Printers

We use the latest professional-grade FDM and MSLA machines to deliver high-quality, consistent, and reliable results. Our printers are capable of producing both large mechanical parts with structural strength and ultra-detailed components with smooth surfaces and intricate features.

Quick Turnaround Time

Time is crucial in product development. Our streamlined workflow and in-house capabilities allow us to offer rapid prototyping with short lead times—so you can move from concept to prototype faster and get to market sooner.

Material Consultation and Optimization

We provide expert advice on material selection based on your application—be it flexibility, strength, temperature resistance, biocompatibility, or aesthetics. From PLA and PETG to engineering resins, we guide you to the most suitable materials for your project’s needs.

Competitive Pricing for Small and Bulk Orders

Whether you’re ordering a single prototype or a batch of parts, our pricing is transparent, flexible, and competitive. We offer cost-effective solutions without compromising quality, making high-end prototyping accessible to startups, small businesses, and large enterprises alike.

Post-Processing Services

We offer a wide range of post-processing options to enhance the performance and appearance of your printed parts, including:

- UV Curing for resin prints

- Sanding and Surface Smoothing

- Painting and Finishing

- Drilling, Tapping, and Assembly

This all-in-one service ensures you receive a fully functional, presentation-ready prototype—not just a raw print.

Applications We Serve

At Fusionise Ltd, our 3D printing design and prototyping services cater to a broad range of industries and use cases. We specialize in creating accurate, functional, and visually refined prototypes that accelerate innovation, support engineering workflows, and enhance product validation across multiple sectors.

Product Development & MVP Testing: Rapidly create and evaluate to assess functionality, ergonomics, and market potential before full-scale production.

Engineering & Mechanical Prototyping: Produce complex mechanical components and functional assemblies for testing fit, form, and function under real-world conditions.

Architectural & Industrial Models: Bring construction and industrial concepts to life with scale-accurate architectural prototypes, urban planning layouts, and infrastructure models.

Custom Enclosures & Functional Housings: Design and fabricate tailored plastic enclosures for electronic devices, tools, IoT systems, and mechanical parts with precision and custom mounting features.

Tooling, Jigs & Fixtures: Streamline your production line with custom jigs, fixtures, alignment tools, and low-volume tooling components designed for efficiency and repeatability.

Replacement Parts & Low-Volume Manufacturing: Manufacture spare parts, legacy components, or low-volume end-use parts where traditional manufacturing would be too costly or slow.

Educational & Demonstration Models: Support classroom teaching, technical training, or stakeholder presentations with physical models that clearly represent complex systems or processes.

Whether you’re in product design, engineering, manufacturing, architecture, or education, Fusionise Ltd delivers tailored 3D printing solutions to meet your prototyping and development goals with speed and precision.

How It Works

At Fusionise Ltd, we make the journey from concept to prototype simple, fast, and collaborative. Whether you’re starting from a sketch or need support with complex mechanical or machine design, our streamlined process ensures accuracy, transparency, and high-quality results at every stage.

1. Submit Your Idea: Share your project with us—this could be in the form of a hand-drawn sketch, CAD file, physical sample, or simply a concept. We welcome projects at any stage of development. If you’re working on a complex assembly or machine, our team will assess functional requirements and system-level interactions to help define a design strategy.

2. Get a Quote & Technical Review: We’ll evaluate your design, intended use, functional demands, and recommended materials. For more complex assemblies or machine components, we may request a short technical brief. Based on this, we’ll provide:

- A detailed, transparent quote

- Suggestions for design improvements

- Estimated lead time and delivery schedule

3. Design, Model & Optimize: Our design team will create or refine a 3D model optimized for FDM or MSLA 3D printing. For machine design projects, we focus on modular design, printability, load-bearing structures, and assembly compatibility. Every model goes through:

- Design for Additive Manufacturing (DfAM)

- File validation and mesh repair

- Simulation and tolerance checks (if needed)

4. 3D Printing & Post-Processing: We produce your parts using our industrial-grade FDM or MSLA printers. Depending on your project’s purpose—visual, functional, or mechanical—we choose the most appropriate print settings, materials, and orientation. After printing, parts are cleaned, cured, and post-processed to meet your required finish or performance specs.

5. Quality Check & Delivery: All prototypes undergo visual and dimensional inspection before dispatch. Final products can be shipped directly to your address or collected in person. For multi-part mechanical systems or machine assemblies, we offer basic pre-fitting and packaging support to ensure safe delivery and ease of reassembly.

Ready to Start Your Project? Get in Touch

We’re excited to work with you on your next idea—whether it’s a prototype, a custom mechanical part, or a complete machine design. If you’re ready to begin or simply want to explore how we can support your project, we’re here to help.

Please send us an email (info@fusionise.co.uk) with a brief description of your project, any relevant sketches or design files, and your specific requirements. Our team will review your inquiry and get back to you promptly with tailored advice and a quotation.

To help us serve you better, feel free to include:

- A short overview of your idea or objective

- Any drawings, CAD models, or photos (if available)

- Intended use or performance expectations

- Preferred material or printing method (if known)

- Deadline or delivery timeframe

Let’s bring your concept to life with precision, speed, and innovation—powered by Fusionise Ltd.